The differentiated application of throttle body materials allows MAGRNA’s throttle bodies to meet and guarantee the requirements of diverse application scopes and conditions. These include, for instance, high-temperature environments, EGR applications, off-road engines, as well as engines fueled by gasoline, diesel, natural gas, alcohol, and other fuels.

+ LEARN THE DIFFERENCE

THE DIFFERENCE

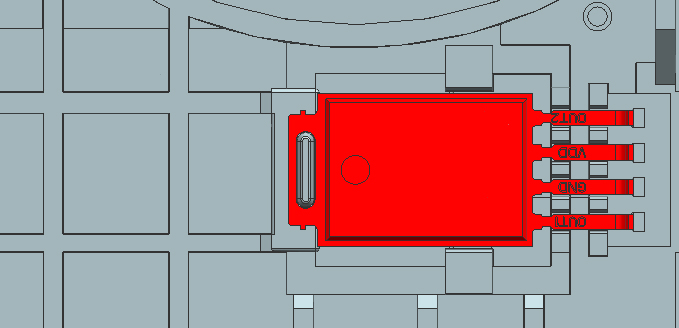

Using Melexis chips

Be widely used in the automotive and industrial electronics fields

Operating Temperature: -40℃~+150℃

High precision and resolution, strong anti-interference capabilities

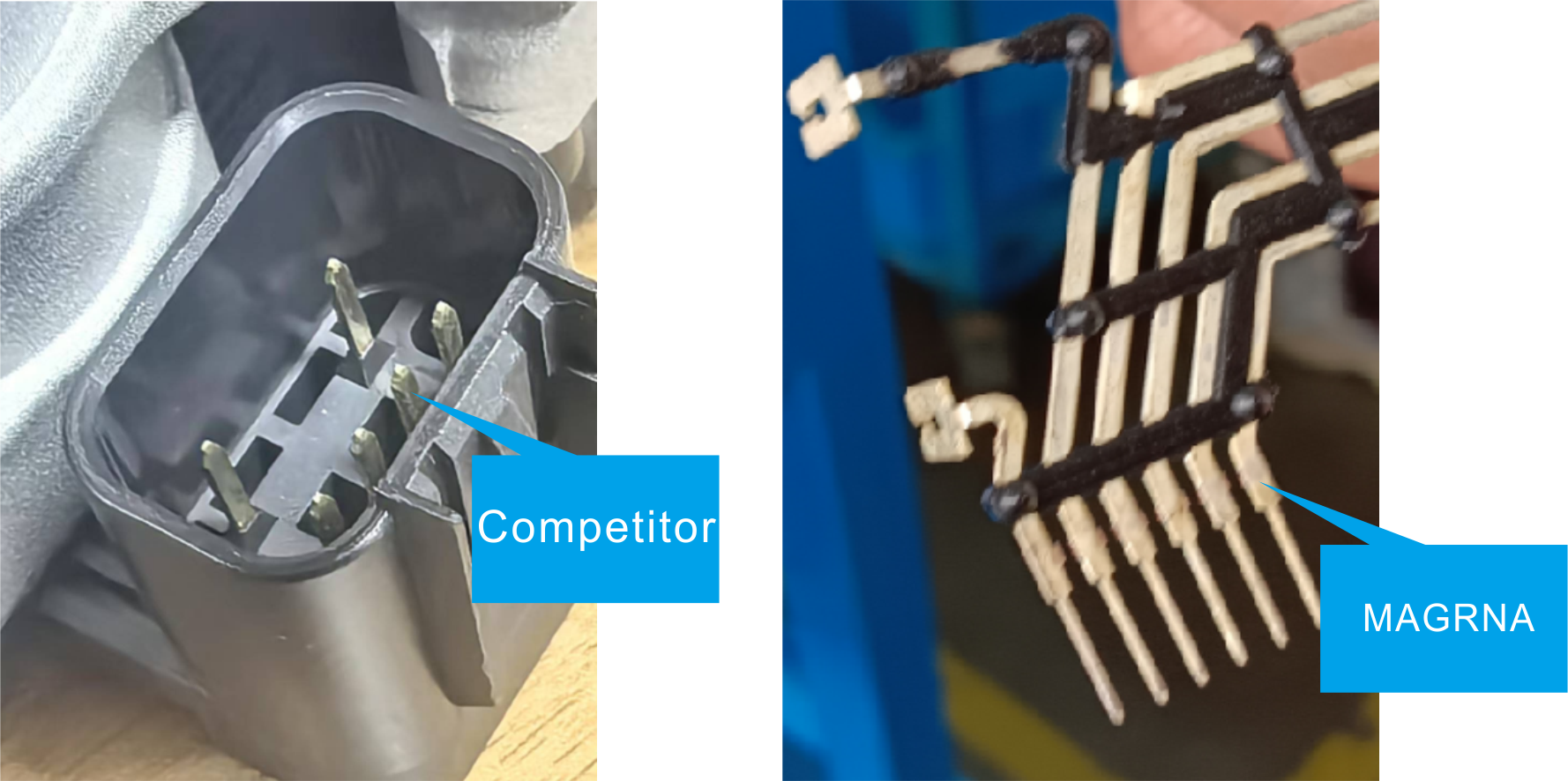

Using QSn6.5-0.1 copper alloy

The surface is silver-plated, with superior conductivity, excellent solderability, and resistance to corrosion and oxidation

Excellent wear resistance, elasticity, and electrical conductivity. Widely used in electrical and mechanical applications.

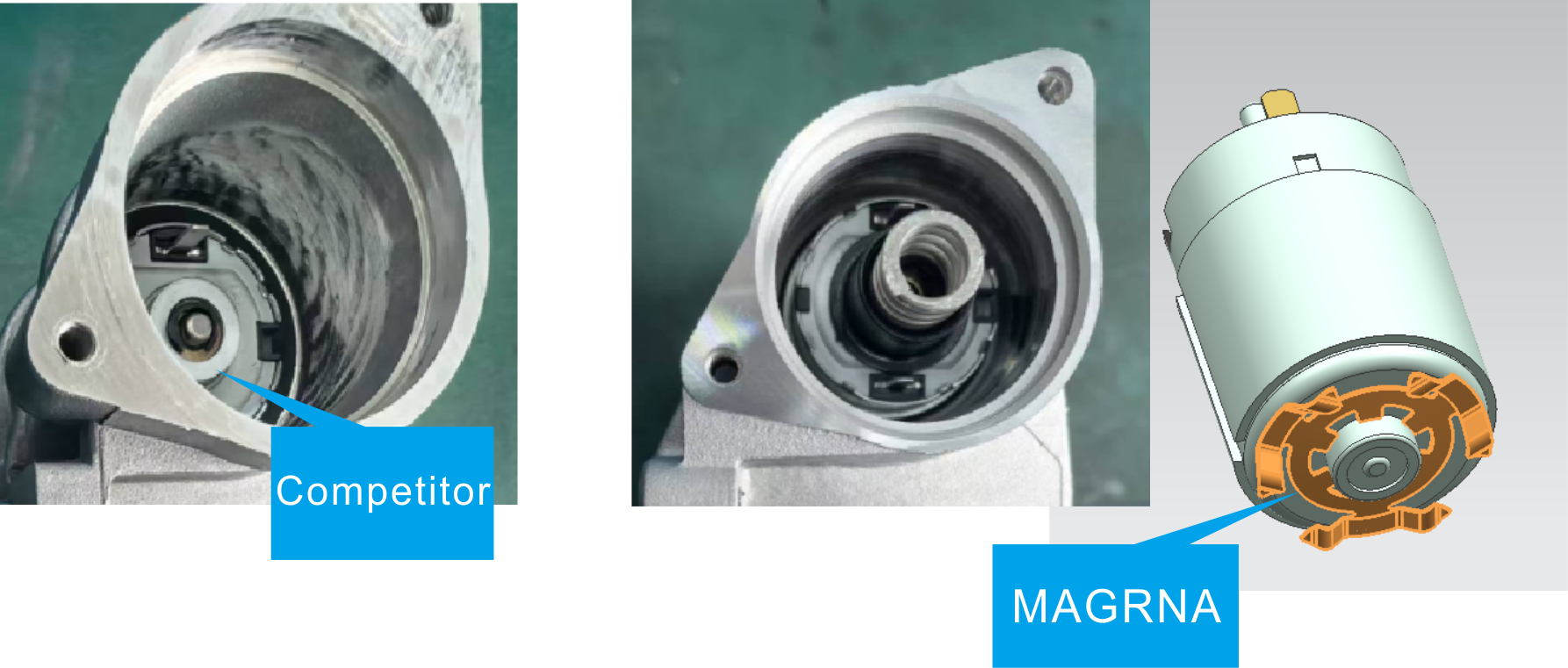

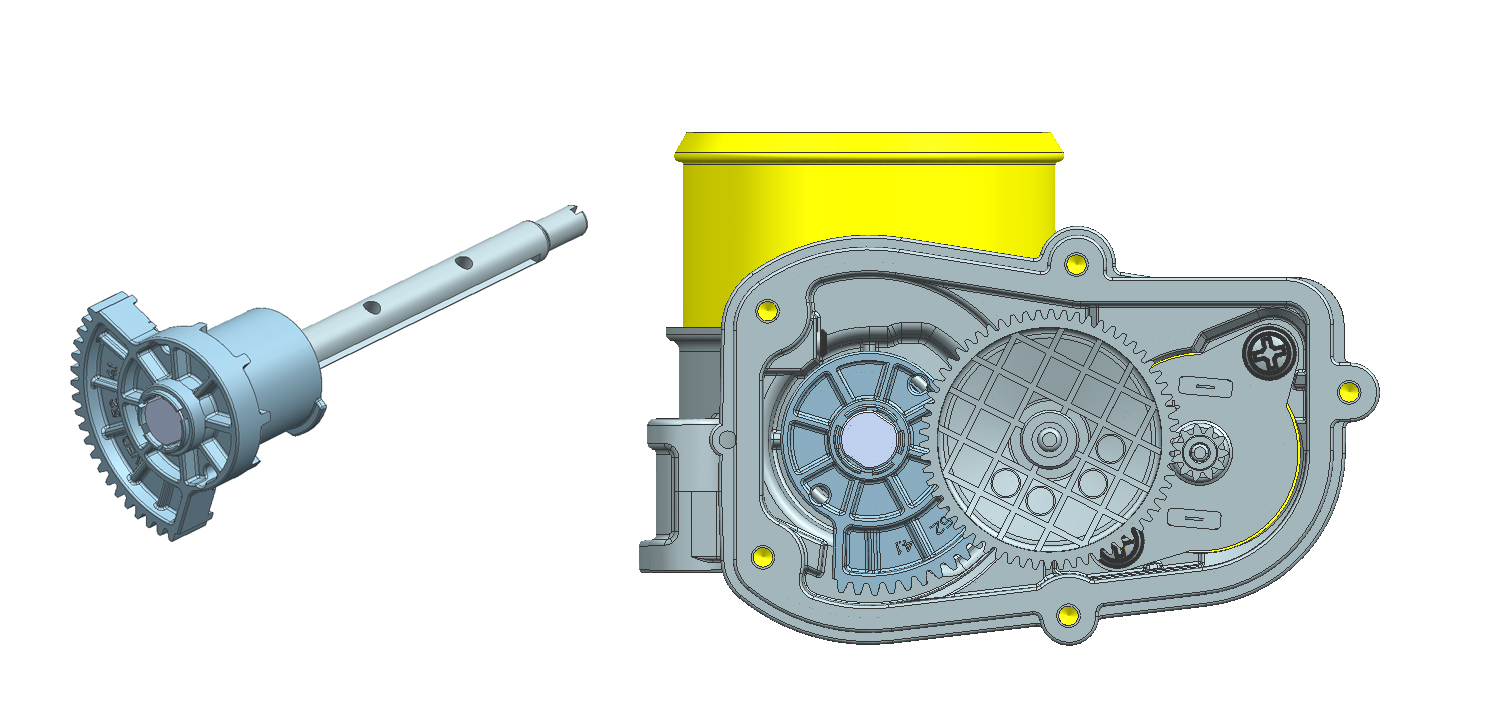

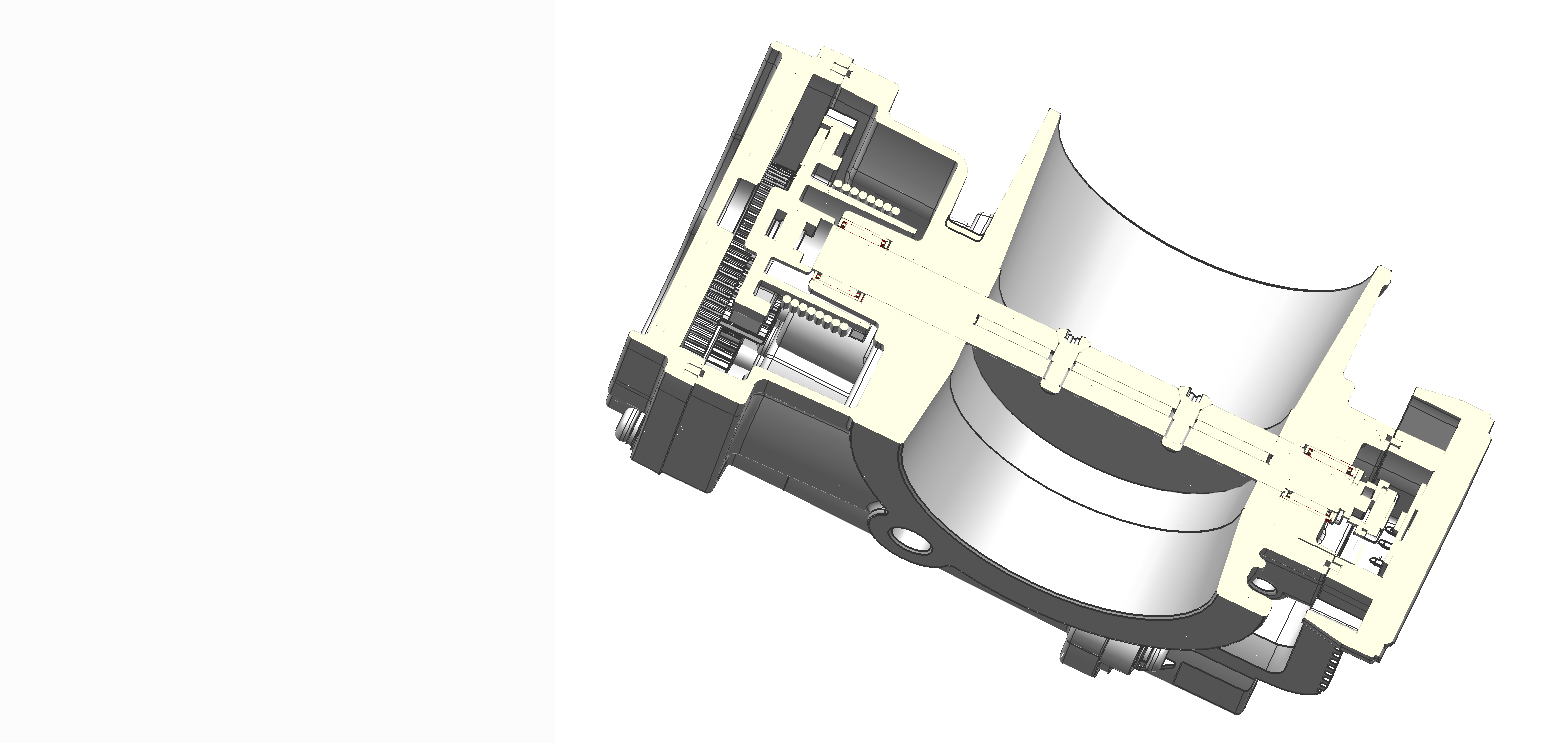

The motor is fixed with an anti-vibration structural design.

Springs and spring sleeves are used to fix the bottom of the motor.

The springs ensure that the motor won't have poor electrical contact due to vibration.

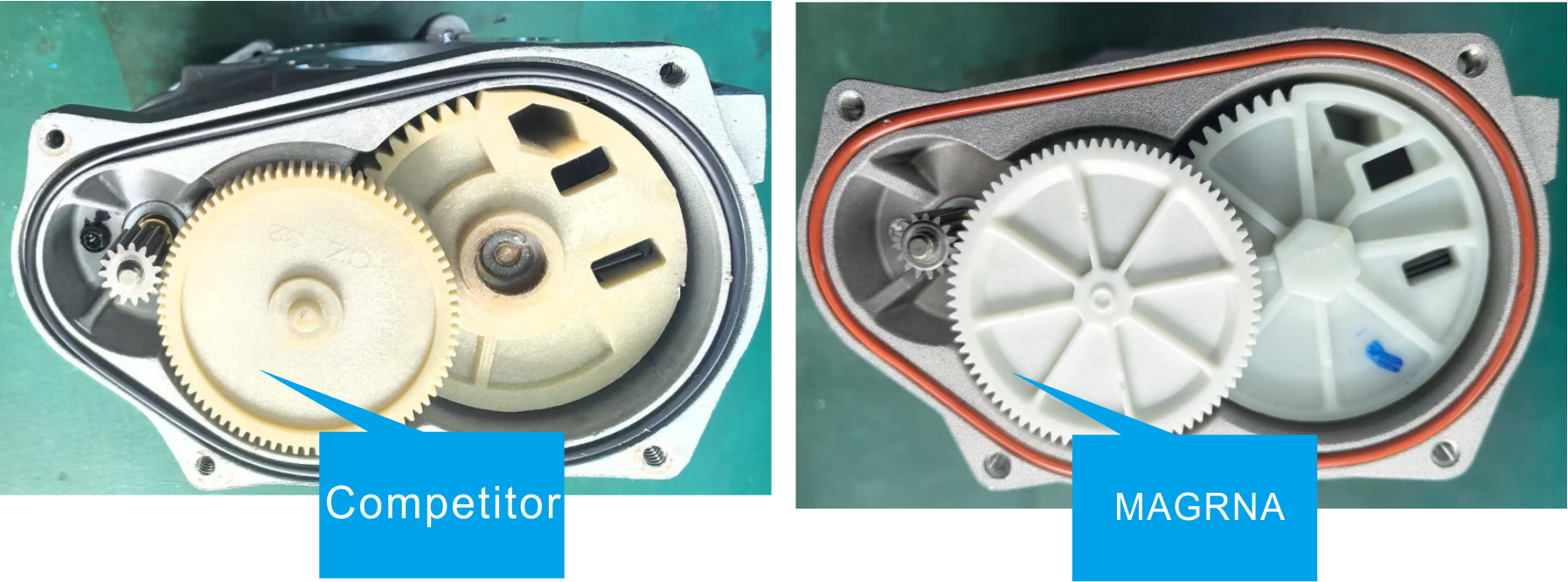

The sector gear is made by PA66 + GF30.

The transmission gear is made by PA66 + GF30 + PTFE Higher strength, lighter weight, more wear-resistance and lower noise, and is adaptable to diverse working conditions.

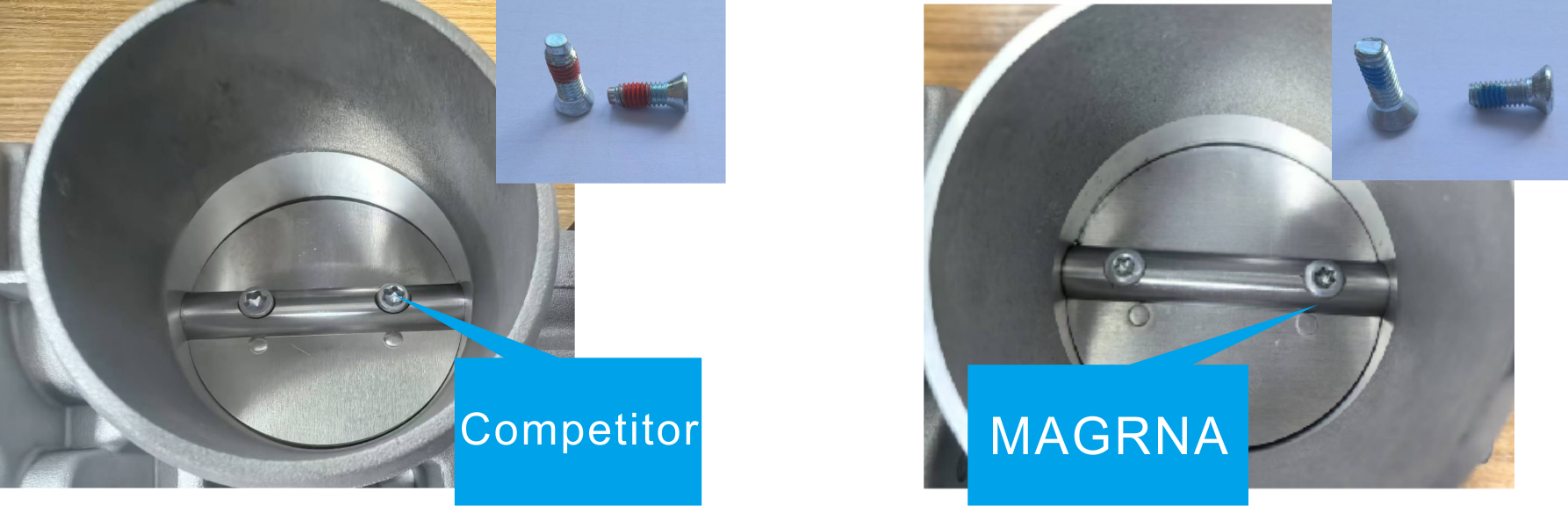

Our design is combined the triangular self-locking screws with high quality pre-applied thread glue

Double anti-loosening mechanism, the reliability is significantly improved

+ PRODCUT CORE FUNCTIONS

The products are designed using platform approaches gear transmission system with high reliability.And the product competitiveness is improved because of its low investment and cost.

The unit design of the high-reliability non-contact angle sensor features the following advantages:

A PCB-free structure boasting excellent weather resistance;

Single-chip packaging with an integrated EMC (Electro Magnetic Compatibility) anti-noise loop, delivering superior anti-electromagnetic interference performance;

Versatile adaptability in both signal output and model specifications to cater to diverse customer requirements;

Exceptional product consistency and pass rate, which significantly reduces scrap costs while enhancing overall product competitiveness.

The product's mechanically robust structural design incorporates needle roller bearings at both ends, which reduces the frictional resistance during shaft rotation. This design effectively prevents throttle body jamming even under severe carbon deposition conditions, thereby significantly lowering after-sales costs and enhancing product competitiveness.

01 Throttle Body

02 Sensors

03 Actuators

04 Solenoid Valve

05 Related Products