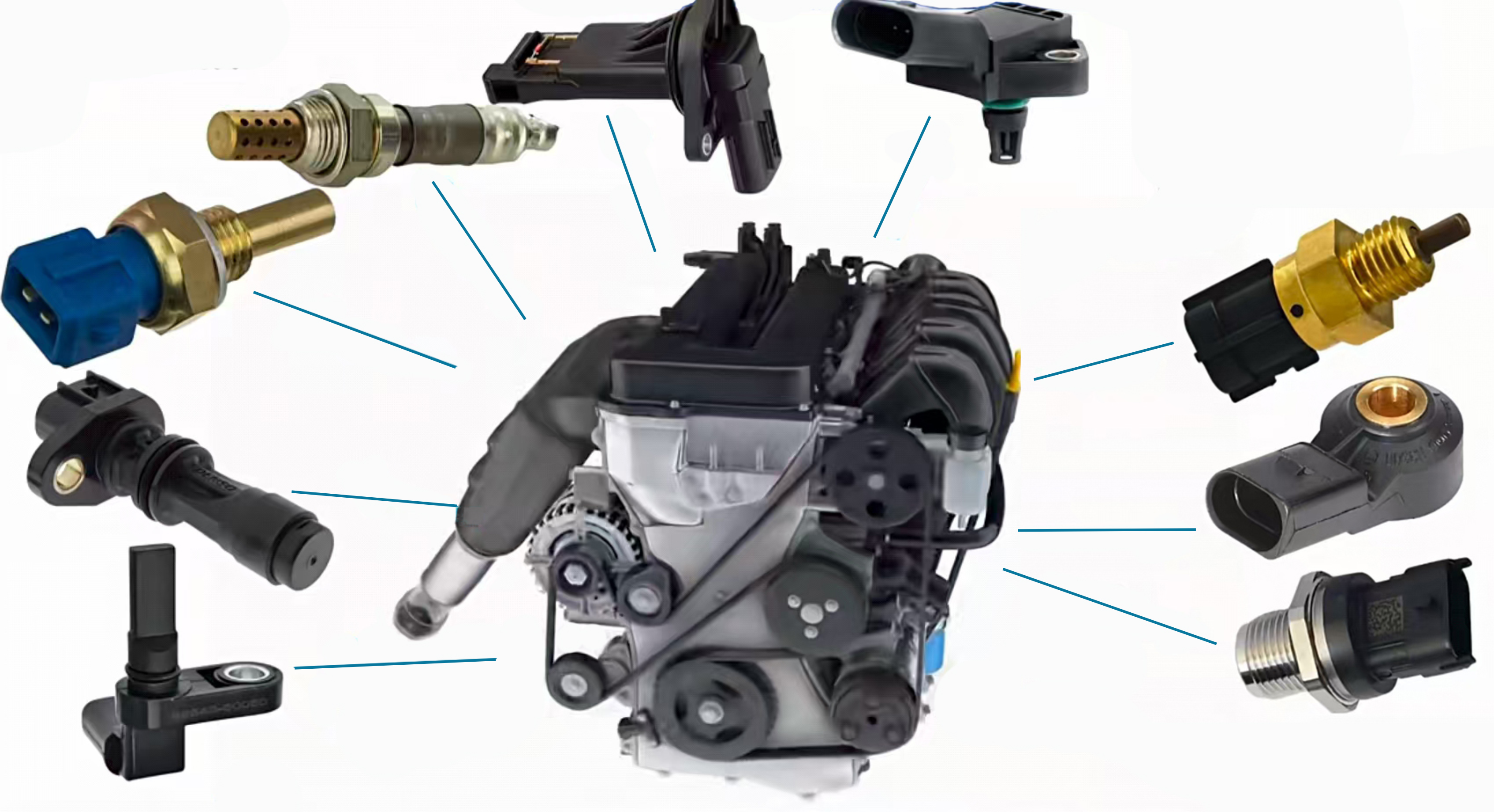

Operating conditions requirements for MAGRNA sensors:

1.Temperature adaptability

2.Vibration and impact resistance

3.Protection rating

4.Electromagnetic compatibility (EMC)

5.Response speed and accuracy

6.Durability

+ LEARN THE DIFFERENCE

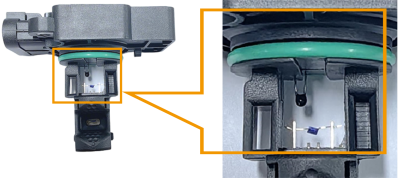

THE DIFFERENCE

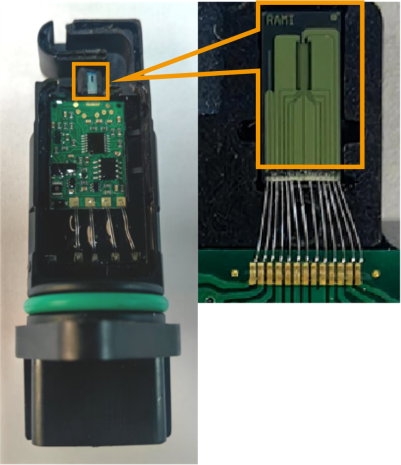

Chips imported from Melexis, Infineon, Freescale, NXP and other leading manufacturers are adopted to ensure the product's higher precision and durability.

Hot-film sensors are widely used in vehicle models with higher requirements for emissions and power performance. Compared with hot-wire sensors, they offer higher measurement accuracy, faster response speed, stronger structural durability, lower intake resistance, and a wider range of applications.

Use PT1000 from Heraeus (Germany) for the thermistor Long-term stability, high vibration resistance High precision and interchangeability

Continuous laser welding machine with a power of 1 KW, which ensures a welding depth of 1.5 mm-2 mm.

Key processes patented

Genuine MAGRNA Quality

MAGRNA Sensors are designed, manufactured, and tested to our premium quality standards.

The products undergo full-process automated inspection to eliminate defective items, ensuring consistency upon delivery and guaranteeing long-term, trouble-free, and exceptional performance.

01 Sensors

02 Throttle Body

03 Actuators

04 Solenoid Valve

05 Related Products